Home / Product Line

Pharmacy Jar Manufacturer

Jesper PET preform Corporation has a diversified product range to serve multiple industries, with pharmacy jar, pharmacy preform, PET preform industry being the main industry served. Our products are highly demanded by our clients across the country for optimum quality. In order to ensure longer service life and reliability, our products are manufactured by our vendors using the best quality raw material and latest technology. Also, pharmacy jar is one of our main products, featuring its high quality and a wide range of applications.

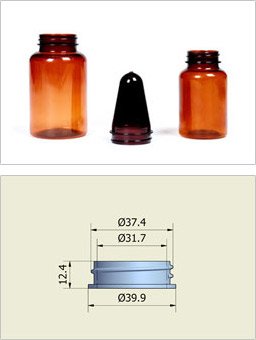

Pharmacy Jar PET Preform

Pharmacy Jar PET Preform

- Non-Crystallized Pharmacy Jar PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

- definitely find most suitable Preform for Bottle design

Jesper PET preform Corporation’s mission is to deliver outstandingpharmacy jar, pharmacy preform, PET preform with such a gratifying experience that our customers become our best advocates. Our products are highly accepted in domestic and international markets, due to their high efficiency and reliability. We fulfil the demands of the Taiwan market as well as of the overseas market, especially the Taiwan market. Please feel free to contact us if you are looking for a reliable pharmacy jar, pharmacy preform, PET preform manufacturer.