Home / Product Line

Plastic Bottle Preform

Jesper PET preform Corporation is one of the leading manufacturers of the plastic bottle preform, and is highly regarded for its quality products. With our expertise, we have been offering quality PET bottle preform renowned for premium features at competitive prices. We ensure that our mineral water preforms goes through different quality tests to maintain the desired quality standards for our offerings. Our adherence to timely and safe delivery of our fine quality water bottle preform has enabled us to maintain long-lasting relationship with our existing clients. Our products made in Taiwan and we provide high quality plastic bottle preform, customized products to achieve customer satisfaction. Interested clients are very welcome to contact us directly!

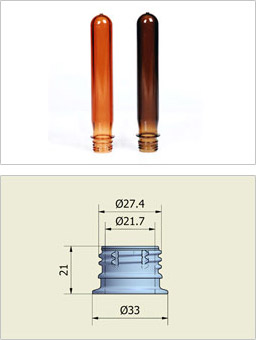

PCO1810 PET Preforms

PCO1810

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO1810-16.5g Long

PCO-1810-16.5g Long

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-16.5g Short

PCO1810-16.5g Short

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-18g

PCO1810-18g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-19g

PCO1810-19g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-20g

PCO1810-20g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-22.5g

PCO1810-22.5g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-23.5g

PCO1810-23.5g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-25g

PCO1810-25g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-27g

PCO1810-27g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-29g

PCO1810-29g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-31g

PCO1810-31g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-33g

PCO1810-33g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-35g

PCO1810-35g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-41g

PCO1810-41g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-45g

PCO1810-45g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

PCO-1810-58.5g

PCO1810-58.5g

- Non-Crystallized PCO-1810 Neck-Finish PET Preform

- Use only Officially approved Graded-A resin

- Applicable for mineral water PET Bottle

- PET Bottles for aseptic products

- Size and Specification fully compliance with international standards

- Absolute low reject rate in blowing process

- Diversify PET Preform weights

- Provide variety of options for customer request interns of weights, neck-finish and colors

Jesper PET preform Corporation, the world’s leading manufacturer of plastic bottle preform, is positioned at the leading edge of innovation and service, providing the most comprehensive plastic bottle preform solutions packages to its customers via a portfolio of highly recognized brands. Our company offers a range of PET bottle preform that is high in quality at affordable prices. For more customized demands that can’t be found in our standard product lines, we also can offer mineral water preforms solution to combine your specific requirements into our newly design standard products. Please do not hesitate to contact us if you are interested in our water bottle preform after referring our website.

Related Product Categories