Core Technology

Core Technology

Jesper PET Preform Co. is extended from DEHKAI Machinery Co. Ltd, therefore has already build solid foundation and capability of manufacture injection molds for PET preform. All products of PCO-1810 PET Preform, 3025 PET Preform, Customized PET Preform, Pharmacy PET Preform and Snap on PET preforms are all made by Jesper’s own molds. This specialty differentiate Jesper PET Preforms Co. with other PET preform manufacturer. Because Jesper could satisfy customer by providing various choice of neck-finish and weights of preforms that suitable for customer’s bottle design. “Sincere Service and Customer Satisfaction” is always the spirit of Jesper PET Preform Co.

PET Preform

PET Preform PET Blow

PET Blow PET Blow

PET Blow PET Blow

PET Blow

Preform

Preform Bottle Blow

Bottle Blow Preform

Preform Preform

Preform

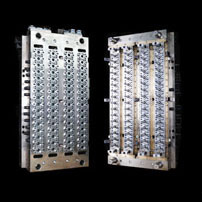

Preform Injection Molds are compose of "Core" "Cavity" "Core Sleeve" "Lip Mold" and "Base Plate", Minimum 4 cavities and up to 64 cavities. Blow Molds can customize base on Blow Molding Machine and Bottle Design. Stable and fast production plus excellent cooling system, the result are beautiful bottles and high quality preforms.

With advanced science and technology, our company develops and manufactures various kinds of PET Blow Molding. We will continue to innovate on our technology, management, services and business to meet future challenges and fulfill our responsibilities.

PET Blow Molding is uses to form the hollow plastic parts. It is a manufacturing process used in the plastics and polymers

industries which is a Process of inflating a hot, hollow, thermoplastic perform or parison inside a closed mold so its shape conforms to that of the mold cavity. A typical blow molding machine set-up uses an extruded plastic preform and compressed air to fill the chamber of a divided mold. The two halves of the mold separate and the finished container are released. The PET Blow Molding is provided in various dimensions and models as per the clients' requirements. These are used in the manufacturing of bottles, pet jars, plastic bottles, plastic jar, mineral water bottles and mineral water jars.

With advanced science and technology, our company develops and manufactures various kinds of PET Blow Molding. We will continue to innovate on our technology, management, services and business to meet future challenges and fulfill our responsibilities.

PET Blow Molding is uses to form the hollow plastic parts. It is a manufacturing process used in the plastics and polymers

industries which is a Process of inflating a hot, hollow, thermoplastic perform or parison inside a closed mold so its shape conforms to that of the mold cavity. A typical blow molding machine set-up uses an extruded plastic preform and compressed air to fill the chamber of a divided mold. The two halves of the mold separate and the finished container are released. The PET Blow Molding is provided in various dimensions and models as per the clients' requirements. These are used in the manufacturing of bottles, pet jars, plastic bottles, plastic jar, mineral water bottles and mineral water jars.